Yep. Can even be wd40 if thats all you got. Just want to keep it coolSweet, that's doable! Hit it with cutting oil as well right?

Form 1

- Thread starter roadsignmcclanahan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

That makes sense. Okay, low rpms, and keep it cool while holding pressure. That’s doable! If I mess up I just won’t admit it on here. HahaYep. Can even be wd40 if thats all you got. Just want to keep it cool

Titanium drills easy if you do it right. Run the rpms pretty slow, but feed the drill with a good amount of force. You have to get under the work hardening layer. Get a quality cobalt (material not lowes brand) drill bit and go at it.

Beat me to it... I was going to say cobalt drill bit. And if you want nice, clean, chatter-free holes, drill 0.002" undersize and finish with a reamer. McMaster is your friend (although more expensive than some other places).

Don't know the diameter for .30 can... but could measure mine tomorrow if needed.

That makes sense. Okay, low rpms, and keep it cool while holding pressure. That’s doable! If I mess up I just won’t admit it on here. Haha

... and use a drill press.

Edit- with a good clamp mounted to the table.

Like mama always said, length and girth are a girls personal preference.After putting off for years to get into the suppressor game. I filed a form 1 on September 2nd, tax stamp rolled in on the 25th. Pretty nice turn around not gonna lie. So anyway, figured I’d build one, after @Axeman talked me into it.

Titanium tube, stainless baffles. I do have the the stamp, but I haven’t started drilling. Sent the tube to get my info engraved.

May be a little long on the 300 BLK. View attachment 101988

View attachment 101987

Idk seems pretty involved, what if i just shoot it out? I’m kidding. After reading so many Form 1 forums it seems like the consensus is to oversize by .060...but also they use 3/8” bits but that would oversize to .375. McMaster is is! Just got a package from them earlier hahaBeat me to it... I was going to say cobalt drill bit. And if you want nice, clean, chatter-free holes, drill 0.002" undersize and finish with a reamer. McMaster is your friend (although more expensive than some other places).

Don't know the diameter for .30 can... but could measure mine tomorrow if needed.

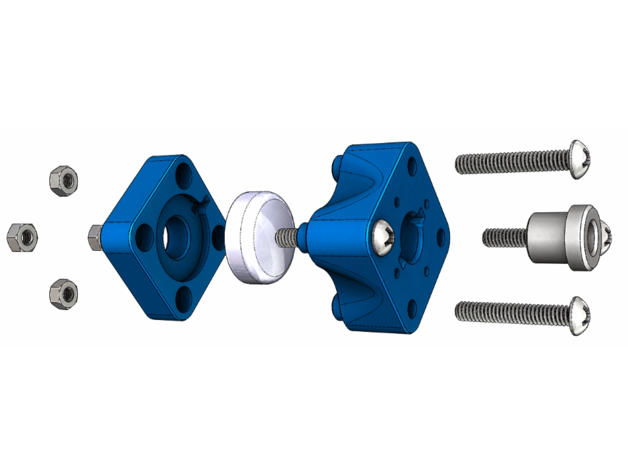

F1 Drill Jig Freeze Plug (requires hardware) by eRock

This jig or fixture was created to assist in drilling properly centered holes in 34.3mm automotive freeze plugs. This version requires the following hardware:2x or 4x 1/4"-20 x 1-1/2" machine screws2x or 4x 1/4"-20 hex nuts5/8" diameter drill bushing (for desired drill size) with headJig...

Going to print this tomorrow. Assuming my pi is still running octoprint...as long as the crap PLA I have will just be enough to hold it I should be good to go!

This may be completely wrong. But I’m not a machinist by any means...just wait until you all see my welds...yeee...But since I’m doing this on a drill press would it make more sense to overbore it a little? Use the 3/8” and just make sure it’s all centered? And use a bore rod?Exit diameter is 0.363" on mine.

This may be completely wrong. But I’m not a machinist by any means...just wait until you all see my welds...yeee...But since I’m doing this on a drill press would it make more sense to overbore it a little? Use the 3/8” and just make sure it’s all centered? And use a bore rod?

Well, I've never tried this before, so not sure. But I am sure that bigger holes are less likely to get clipped by a projectile.

Gotta be a mom joke in there somewhere....But you are for sure right on that...I'm sure it wouldn't help suppression as much, but man would I prefer this not to blow up in my face.Well, I've never tried this before, so not sure. But I am sure that bigger holes are less likely to get clipped by a projectile.

You may want to drill a pilot hole with a drill bit half the size of the finish hole. Do not be afraid to clamp that sucker down hard since it is titanium. Just make sure not to roll the threads. Also, drill from the back side out (threads up towards drill bit) so that you can file off any flashing left from drilling.This may be completely wrong. But I’m not a machinist by any means...just wait until you all see my welds...yeee...But since I’m doing this on a drill press would it make more sense to overbore it a little? Use the 3/8” and just make sure it’s all centered? And use a bore rod?

In all, honesty, having the exit hole a little oversized on the end cap will not hurt anything. I used my Octane 45 on the M11/9 without any noticeable increase in sound. The blast chamber and the baffle stop the muzzle blast. Remember to put a little antisieze on the threads when assembling.

Good luck!

That can be done! I messed around and started drilling out some baffles late last night. Got two drilled out nicely, then bit just up and shit the bed. Got some cobalt ones on order now.You may want to drill a pilot hole with a drill bit half the size of the finish hole. Do not be afraid to clamp that sucker down hard since it is titanium. Just make sure not to roll the threads. Also, drill from the back side out (threads up towards drill bit) so that you can file off any flashing left from drilling.

In all, honesty, having the exit hole a little oversized on the end cap will not hurt anything. I used my Octane 45 on the M11/9 without any noticeable increase in sound. The blast chamber and the baffle stop the muzzle blast. Remember to put a little antisieze on the threads when assembling.

Good luck!

Well thanks to all the wonderful insight of all of you. I drilled ‘em out yesterday. Still waiting on my tube to come back, and I haven’t cut spacers yet.

Cobalt made everything stupid simple to drill right through on low rpms and hit it with some cutting oil...which may or may not have been 25 years old.

Not going to lie, I used vice grips to hold them and then went slow but held pressure as I drilled.

Cobalt made everything stupid simple to drill right through on low rpms and hit it with some cutting oil...which may or may not have been 25 years old.

Not going to lie, I used vice grips to hold them and then went slow but held pressure as I drilled.

Score!!!!! In for a range report! Been wanting a second 22lr can. I really should go this route.Well thanks to all the wonderful insight of all of you. I drilled ‘em out yesterday. Still waiting on my tube to come back, and I haven’t cut spacers yet.

Cobalt made everything stupid simple to drill right through on low rpms and hit it with some cutting oil...which may or may not have been 25 years old.

Not going to lie, I used vice grips to hold them and then went slow but held pressure as I drilled.

View attachment 102589 View attachment 102590 View attachment 102591

Well thanks to all the wonderful insight of all of you. I drilled ‘em out yesterday. Still waiting on my tube to come back, and I haven’t cut spacers yet.

Cobalt made everything stupid simple to drill right through on low rpms and hit it with some cutting oil...which may or may not have been 25 years old.

Not going to lie, I used vice grips to hold them and then went slow but held pressure as I drilled.

View attachment 102589 View attachment 102590 View attachment 102591

...I just noticed.... damn that's a lot of baffles!

Said it shipped yesterday...so probably Friday? Maybe Saturday.@Cameron Shepherd when is your tube coming back??

I registered with the ATF. I filled out Form 1....all of this from my iPhone.

When I get the green message at the end, I click "pay"

A window pops up and says I need to pay in another open window....but there's no open window.

This is a pain.

When I get the green message at the end, I click "pay"

A window pops up and says I need to pay in another open window....but there's no open window.

This is a pain.