SkipD said:

I get the impression that you can double or triple your output when making quantities of the same pieces. That's a nice machine.

Will you be able to make your own dies for simpler parts?

How many pieces would you have to make with a die to pay for a die made by the manufacturer with saved time?

Skip,

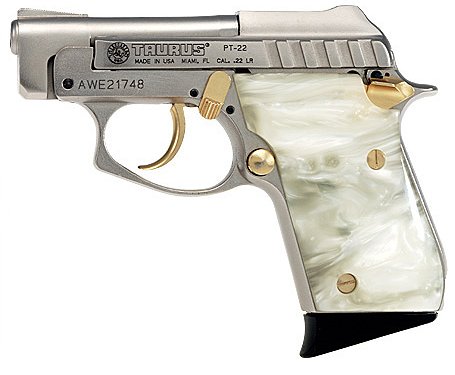

I'm not sure it would double or triple my out put, but it would help with my output for sure. For instance, I make a lot of Ruger LCP holsters and have a pattern for that gun. Same pattern used for standard gun, LaserMax, and Crimson Trace (just use different molds). So I could take a hide and stamp out 40-50 of them pretty quickly.

I will not make my own dies. Several people make them and that is their only business so they are very good at their work. Plus you need special tools and machines to make bends, curves, angles and such like you see in the video. This machine is kind of a nice to have for me. I do not have to have it. But as I get busier, anything I can do to save time is good. If I ever decide to hire help (and I do not want to do that), it would be a good machine to have. I would have to make a lot of pieces to pay for a clicker and the dies. If I looked at it that way, I'd probably not get it. On the other hand I'm in a very good position in that I do not need income from holster making, but I love making this stuff. So I can put more money into getting machines that make it easier to make leather products. There are several good machines to have in a leather shop, and I'm slowly adding the machines as I can. Some other things on my list are a strap cutter, leather splitter, and another leather sewing machine for thinner stuff/products.